The robust and powerful Zünd “Power Rotary Tool” (PRT) is designed for cutting challenging fibrous materials inexpensively and reliably.

Suitable for cutting with the PRT is a range of materials, including fiberglass and aramid. The tool can be set at 3 different rpm levels, i.e. at 100%, 75%, or 50% of the maximum. This allows for cleanly cutting tough materials as well as those with lower melting points. The PRT consists of a cutting assembly and a connector unit; it inserts into the Universal Module UM-60.

Pressurized air keeps the cutting assembly free of residual fibers and other debris and also cools the motor. Tooth-belt driven, segmented rotary blades serve as cutting tools and are user-exchangeable. To guard against overheating, the temperature of the tool is monitored continually. The cutter displays an error message if temperature levels exceed safe limits.

This makes the PRT ideal for industrial applications that May require prolonged usage in multiple shifts.

Recommended applications for the PRT are:

• Various textiles

• Woven/non-woven composites (aramid,fiberglass, carbon fiber)

Advantages at a glance

- Use of rotary blades reduces drag on material

- Choice of 3 RPM settings (16,000/12,000/8,000)

- Low-impact processing of materials with low melting points

- High throughput; clean, accurate results

- Compatible with G3

-

Rubber

Rubber

-

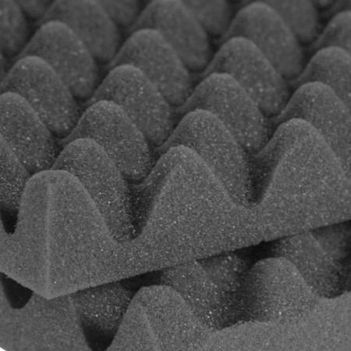

Foam

Foam

-

Textiles

Textiles

-

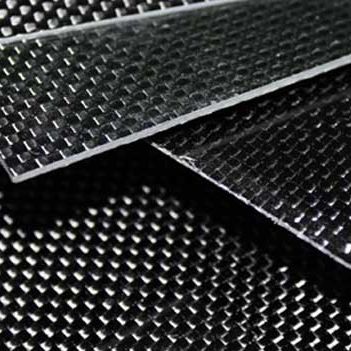

Tech textiles

Tech textiles